REIGNMAC has been deeply engaged in the field of building materials processing for more than 20 years, providing users in more than 70 countries around the world with four-sided processing and double-end processing solutions for wooden doors, wood lines, floors, decorative wall boards, cabinets, bathrooms, wooden houses, furniture and other products.

This year, REIGNMAC combined with the needs of the building materials market, specially launched:

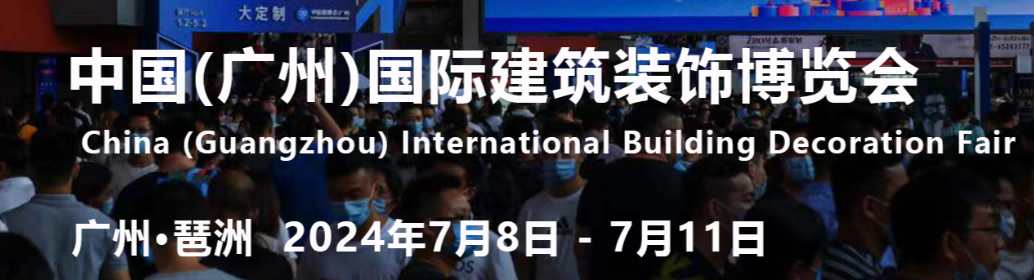

50m/min feeding speed high-speed 4 side moulder

The high-speed four-sided planer can bring stable and good surface quality in 50-meter high-speed machining. From a single machine to an automated connection, REIGNMAC can provide you with a variety of solutions.

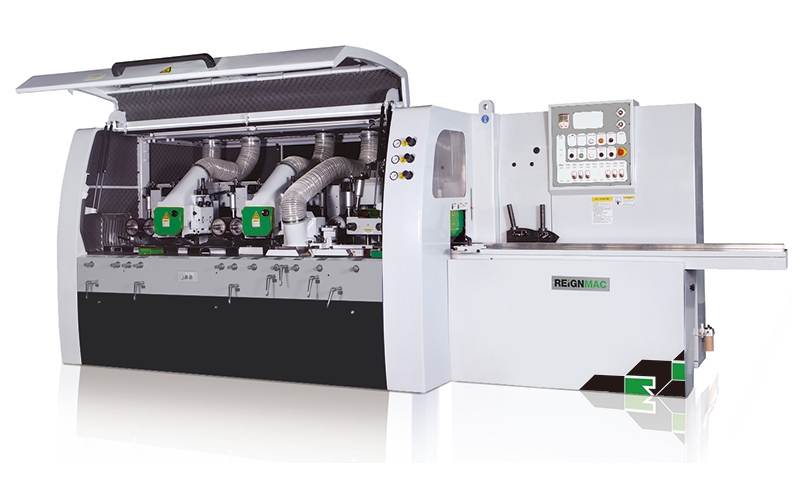

400mm working width heavy duty cutting 4 side moulder

Special processing range, widely satisfied with the needs of greatness workpieces. The Max. working width is 400mm, and the Max. thickness is 300mm.

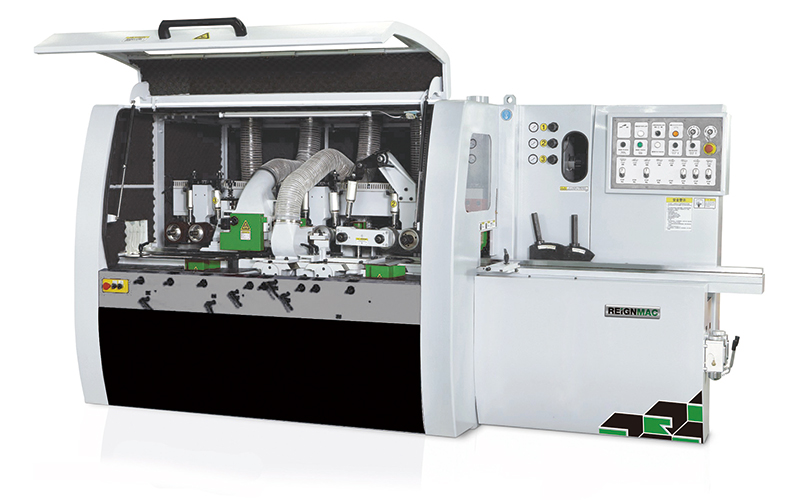

Sanding and milling compound double end tenoner

This is a double-end milling and sanding machine combined into one machine, which can solve the edge milling and sanding process of cabinet door panels, bathroom cabinet door panels, and solid wood furniture at one time, saving manpower, space and turnover

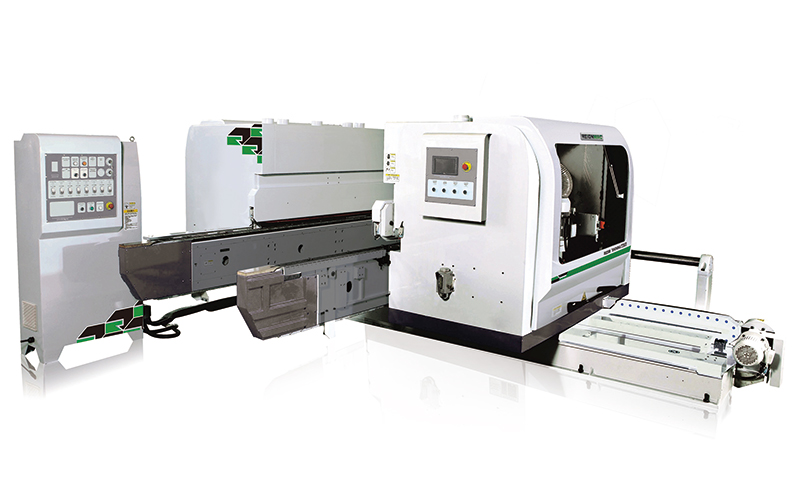

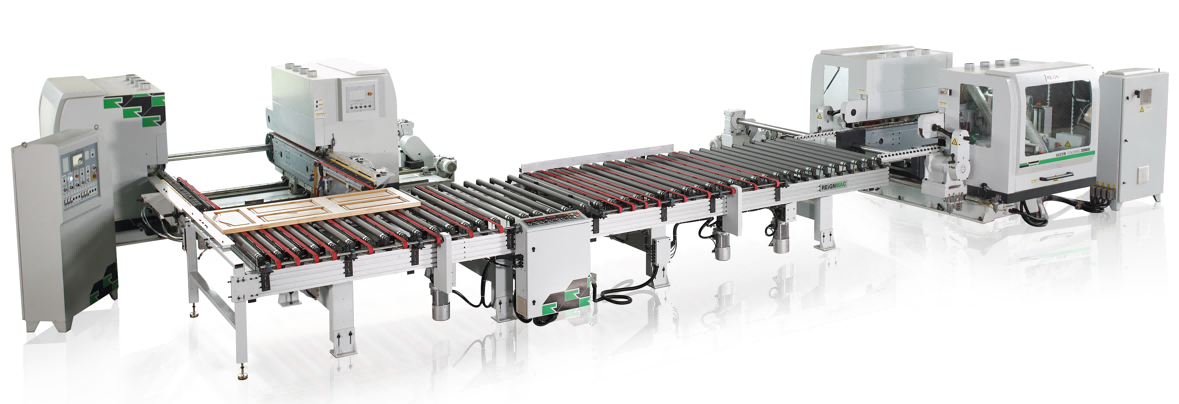

Processing wooden door four sides production line

RMD+RMD double end tenoner + double end tenoner production line is suitable to work the continuous .process for trimming, sizing profiles on four sides of panel workpieces such as solid wood or composites .wooden door, fire door, cabinet door, furniture table, to complete the process at one time. we can according to your needs to design a different combination of wiring program.

We sincerely welcomes new and old customers to visit our factory and learn about the new technology of four side moulder and double end tenoner.