Professional solution for processing reconsolidated bamboo flooring, hardwood strip, large-cutting profile and wooden house beam.

1. Inverter to feed 6-30m/min.

2. Individual motor power for each spindle to ensure maximum cutting power.

3. Ø50mm spindle, heavy load design, more suitable for heavy cutting.

4. According to different models, the last horizontal spindle is equipped with out-ball support bearings, which can better meet the heavy duty cutting process.

5.All adjustment of spindles are centralized in front of machine ,to be convenient to operate.

6. High chrome work table for good durability.

7. The gear case is equipped, to be good for processing the short pieces.

8. The design of double-layer work table is more reliable and effective to ensure the straightness on both sides of work piece.

9.Pneumatic side pressure wheel before left spindle can adjust the side pressure flexibly.

10.First group of feeding roller and chain-wheel box with pneumatic double-direction adjustment for press and raise ,you can make the workpiece feeding or back-feed.

11.Pneumatic front pressure shoe before top spindle is convenient and nimble to adjust.

12.Bottom driving roller is helpful for the feeding purpose.

13.Pneumatic pressure loaded to top feed rollers separately adjustable for easy of feeding with variation in thickness.

14.Manual oil pump lubricated the work table and carriage, centralized lubrication is easy to control.

15.Adopting electric components from international brand with steady quality.

16.Sealed safety enclosure is for the protection against noise and dust ,and it is helpful for the safe operation.

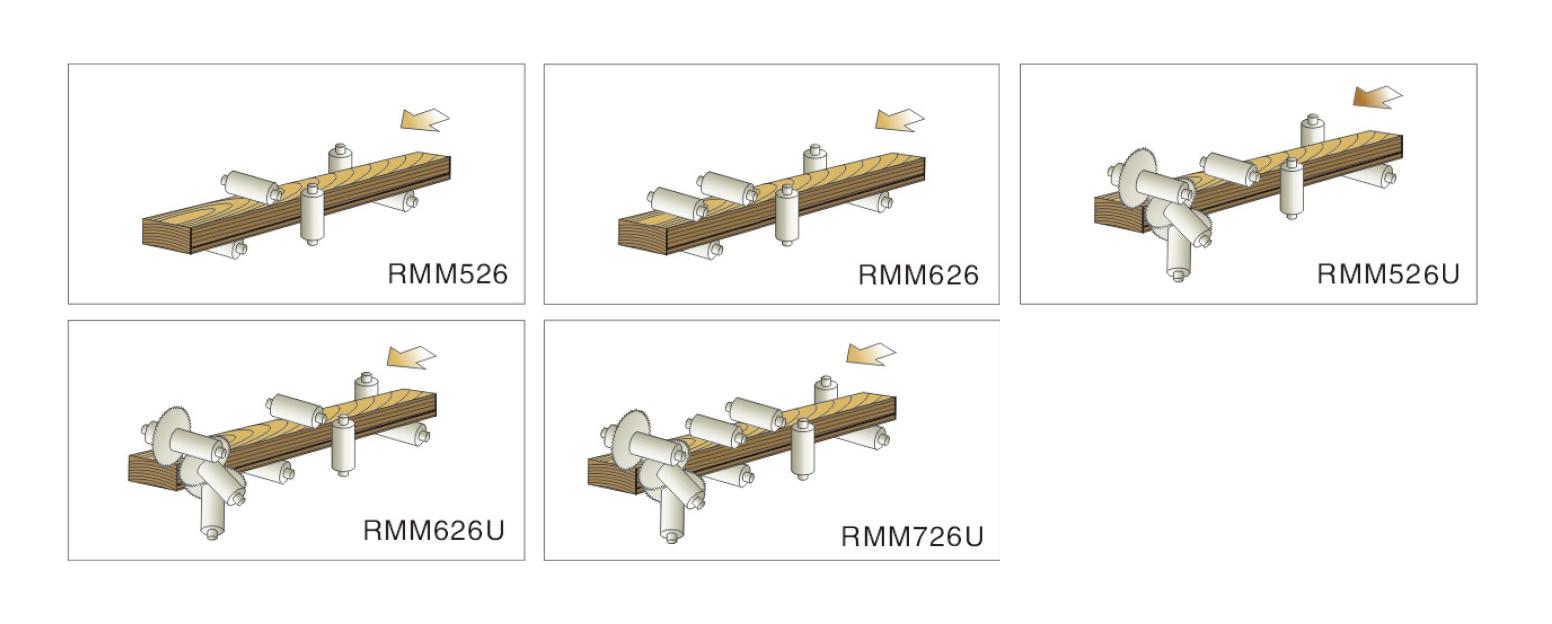

Specification & Type |

RMM626 |

RMM526 |

|

| Working Width | Min. | 20mm | 20mm |

| Max. | 260mm | 260mm | |

| Working thickness | Min. | 8mm | 8mm |

| Max. | 180mm | 180mm | |

| Number of spindles | 6 | 5 | |

| Speed of spindles | 6000r/min | 6000r/min | |

| Cutting circles | Frist bottom spindle | Ø110-Ø145mm | Ø110-Ø145mm |

| Right side spindle | Ø125-Ø200mm | Ø125-Ø200mm | |

| Left side spindle | Ø125-Ø200mm | Ø125-Ø200mm | |

| First Top spindle | Ø110-Ø200mm | Ø110-Ø200mm | |

| Second Top spindle | Ø110-Ø200mm | 一 | |

| Second Bottom spindle | Ø110-Ø200mm | Ø110-Ø200mm | |

| Spindle diameter | Ø50mm | Ø50mm | |

| Basic motor power | First bottom spindle | 7.5 kW/10HP | 7.5 kW/10HP |

| Right side spindle | 7.5 kW/10HP | 7.5 kW/10HP | |

| Left side spindle | 7.5 kW/10HP | 7.5 kW/10HP | |

| First Top spindle | 11 kW/15HP | 11 kW/15HP | |

| Second Top spindle | 11 kW/15HP | - | |

| Second Top Bottom spindle | 11 kW/15HP | 11 kW/15HP | |

| Feed | 5.5kW/7.5HP | 5.5kW/7.5HP | |

| Feed beam rise & fall | 1.1kW/1.5HP | 1.1kW/1.5HP | |

| Total motor power | 62.1kW/84HP | 43.6 kW/59HP | |

| Feed speed(Inverter for feed | 6-30m/min | 6-30m/min | |

| Dust outlet diameter(mm) | 150 | 150 | |

| Overall machine dimensions (L×WxH)(mm) | 4710×1700×1700 | 4280×1700×1700 | |

| Weigh(Tons approx) | 5 | 4.6 | |

Note: Any variation to the specification above mentioned will not be further notified since the product specification and designs keeps on changing.