Professional solution: solid wood or MDF and HDF furniture, wooden door and so on.

1.Inverter feed speed of 6~30m/min

2.Individual motor to each spindle to ensure maximum power transmission

3.High precision spindle units with two pairs of high precision bearings each end of the assembly

4.All main spindle adjustments are carried out from outside the enclosure

5.Hard chromed bed plates to minimise bed wear

6.Short piece driven top feed roller unit for greater feeding control around the right side spindle

7.A group of side pressure wheels on the right side of the left spindle, adjusted the pressure flexible by pneumatic.

8.As our standard, short pieces device with pneumatic double-direction( press and raise) , you can make the workpieces feeding or back in anytime.

9. Pneumatic in-feed bottom helical roller is more suitable for large deformation and high moisture of the wood to feed .

10. Multi-group bottom driving roller to improve the feed effect .

11.Pneumatic pressure loading to top feed rollers separately adjustable, for easy of feeding stock with variation in thickness

12. Adjustable out-feed side pressure plate can meet the different thickness of material output steadily.

13.Manual bed lubrication to reduce friction and improve feeding difficult timbers

14.Adopting electric component from international class with steady quality

15.Sealed safety enclose to reduce noise levels, improve extraction and operator safety

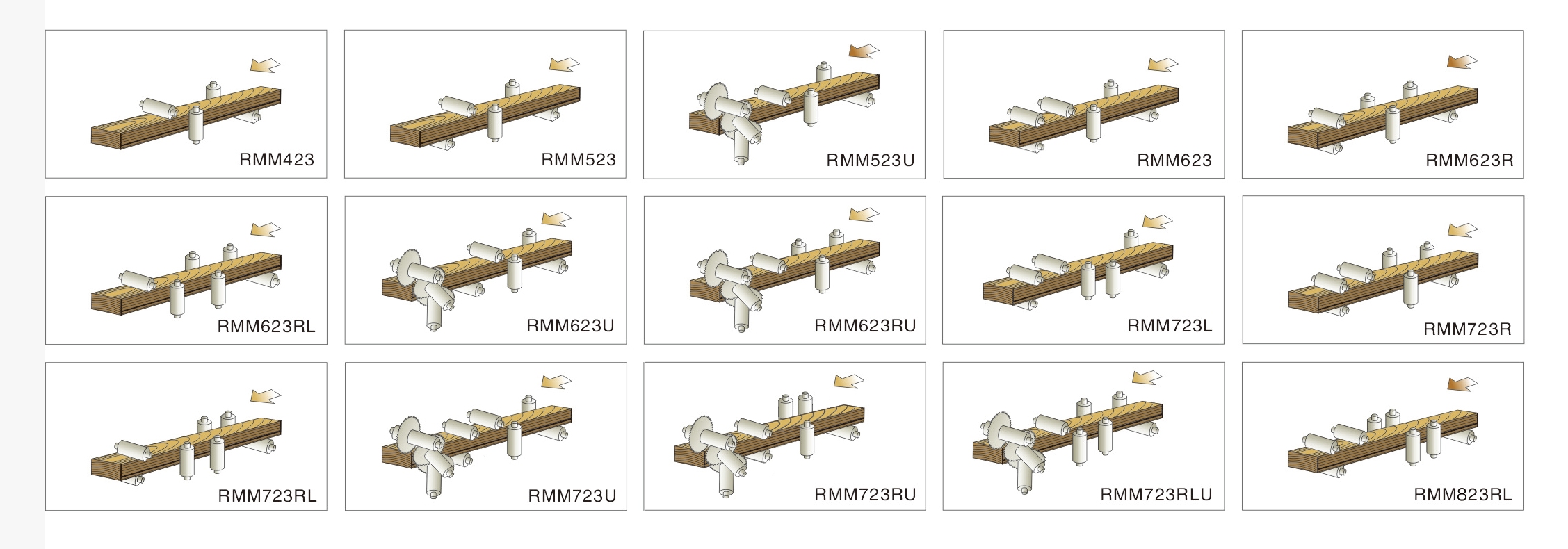

Specification &Type |

RMM623 |

RMM523 |

RMM423 |

RMM723U |

RMM623U |

RMM523U |

|

|

Working Width (mm) |

Min. |

20 |

20 |

20 |

20 |

20 |

20 |

|

Max. |

230 |

230 |

230 |

230 |

230 |

230 |

|

|

Working Thickness (mm) |

Min. |

8 |

8 |

8 |

8 |

8 |

8 |

|

Max. |

160 |

160 |

160 |

160 |

160 |

160 |

|

|

Number of spindles |

6 |

5 |

4 |

6+1 |

5+1 |

4+1 |

|

|

Speed of spindes(r/min) |

6000 |

6000 |

6000 |

6000 |

6000 |

6000 |

|

|

Cutting circles (min~max) (mm) |

First Bottom Spindle |

Ø110 ~ Ø145 |

Ø110 ~ Ø145 |

Ø108 ~ Ø145 |

Ø110 ~ Ø145 |

Ø110 ~ Ø145 |

Ø108 ~ Ø145 |

|

Right side Spindle |

Ø110 ~ Ø200 |

Ø110 ~ Ø200 |

Ø108 ~ Ø200 |

Ø110 ~ Ø200 |

Ø110~ Ø200 |

Ø110 ~ Ø200 |

|

|

Left side Spindle |

Ø110~ Ø200 |

Ø110~ Ø200 |

Ø108 ~ Ø200 |

Ø110~ Ø200 |

Ø110 ~ Ø200 |

Ø110~ Ø200 |

|

|

First Top Spindle |

Ø110 ~ Ø200 |

Ø110 ~ Ø200 |

Ø108 ~ Ø200 |

Ø110~ Ø200 |

Ø110 ~ Ø200 |

Ø110~ Ø200 |

|

|

Second Top Spindle |

Ø110~ Ø200 |

~~~~~ |

~~~~~ |

Ø110 ~ Ø200 |

~~~~~ |

~~~~~ |

|

|

Second Bottom Spindle |

Ø110~ Ø200 |

Ø110 ~ Ø200 |

~~~~~ |

Ø110 ~ Ø200 |

Ø110 ~ Ø200 |

~~~~~ |

|

|

Universal spindle |

~~~~~ |

~~~~~ |

~~~~~ |

Ø110 ~Ø180 |

Ø110 ~Ø180 |

Ø110~ Ø200 |

|

|

Max. Length for installing cutter block(mm) |

~~~~~ |

~~~~~ |

~~~~~ |

240 |

240 |

240 |

|

|

Spindle diameter (mm) |

Ø40 |

Ø40 |

Ø40 |

Ø40 |

Ø40 |

Ø40 |

|

|

Rotation angle for universal spindle |

~~~~~ |

~~~~~ |

~~~~~ |

360° |

360° |

360° |

|

|

Basice motor powers (kW) |

First Bottom Spindle |

5.5 kW/7.5HP |

5.5 kW/7.5HP |

5.5 kW/7.5HP |

5.5 kW/7.5HP |

5.5 kW/7.5HP |

5.5 kW /7.5HP |

|

Right side Spindle |

5.5 kW/7.5HP |

5.5 kW/7.5HP |

5.5 kW/7.5HP |

5.5 kW/7.5HP |

5.5 kW/7.5HP |

5.5 kW /7.5HP |

|

|

Left side Spindle |

5.5 kW/7.5HP |

5.5 kW/7.5HP |

5.5 kW/7.5HP |

5.5 kW/7.5HP |

5.5 kW/7.5HP |

5.5 kW /7.5HP |

|

|

First Top Spindle |

7.5 kW/10HP |

7.5 kW/10HP |

7.5 kW/10HP |

7.5kW/10 HP |

7.5kW/10 HP |

7.5kW /10 HP |

|

|

Second Top Spindle |

5.5 kW/7.5HP |

- |

- |

5.5 kW/7.5HP |

- |

- |

|

|

Second Bottom Spindle |

7.5 kW/10HP |

7.5 kW/10HP |

- |

7.5kW/10 HP |

7.5kW/10 HP |

- |

|

|

Universal spindle |

- |

- |

- |

7.5kW/10HP |

7.5kW/10HP |

7.5kW /10HP |

|

|

Universal spindle rise & fall |

- |

- |

- |

0.18kW/0.25HP |

0.18kW /0.25HP |

0.18kW /0.25HP |

|

|

Feed |

4kW/5.5HP |

3kW/4HP |

3kW/4HP |

5.5kW/7.5HP |

4W/5.5HP |

3kW/4HP |

|

|

Feed beam rise & fall |

1.1kW /1.5HP |

1.1kW /1.5HP |

1.1kW /1.5HP |

1.1kW /1.5HP |

1.1kW /1.5HP |

1.1kW /1.5HP |

|

|

Total motor power(KW) |

42.1kW /57HP |

35.6kW /48HP |

28.1kW /38HP |

51.28kW /69.25HP |

44.28kW /59.75HP |

35.78kW /48.25HP |

|

|

Feed speed (m/min) (Inverter ) |

6~30 |

6~30 |

6~30 |

6~30 |

6~30 |

6~30 |

|

|

Dust pipe diameter (mm) |

Ø150 |

Ø150 |

Ø150 |

Ø150 |

Ø150 |

Ø150 |

|

|

Overall machine dimensions (L×W×H) (mm) |

4760×1676 ×1730 |

3740×1656× 1730 |

3540×1656× 1730 |

5705×1676 ×1800 |

4690×1676 ×1800 |

4447×16 76×1800 |

|

|

Weight (tons approx) (T) |

4.6 |

3.8 |

3.4 |

6.1 |

4.8 |

4.5 |

|

Note:Any variation to the specification above mentioned will not be further notified since the product specification and design keeps on changing all the time