Professional solution for heavy cutting of extra large wooden house beams and columns, and ultra-wide mouldings processing.

1.Special processing range, widely satisfy with the needs of greatness workpieces. The Max. working width is 400mm, and the Max. thickness is 300mm.

2. Each spindle with the diameter of 50mm. The out bearing on the horizontal spindles can increase the carrying capacity. The Max. outer diameter of cutting circle reaches 230mm, this is good to improve the machining quality.

3. The power feeding system consists of multiple sets of 180mm diameter upper feed rollers and multiple sets of bottom rollers. The feed system is fully powered to ensure a strong feeding capacity and the first set of bottom rollers are simultaneous lifting and lowering makes adjustment easier.

4. High chromed work table for good durability.

5.The left and right spindles are designed to adopt double-desk working table. The axial adjustment range is 80mm. As it can hold two groups of cutter blocks, it is flexible for machining.

6.The working thickness of top spindle and the working width of left spindle are adopt electric setting. Higher precision and easier to operate.

7.Each feeding roller , side pressure wheels, front and rear preasure board of top spindle are pressed by pneumatic. The pressure can be adjusted and it is convenient to control.

8. Motion adjustment is widely adopted pneumatic-locking each spindle and the inter-lock with the electric system is for safety and simplify operations.

9. For the 2nd bottom spindle, There is individual motor automaticly to lift the top pressure shoe, and the saw blade installed reaches the diameter of 300mm .The top pressure shoe which is controlled by pneumatic enlarged the working range as well.

10. To assure powerful cutting, the spindles are with high-power motor and driven by synchronous belt.

11. Inverter feed speed of 5-25m/min.

12. Electric oil pump lubricates the working table in timing and ration (which can be adjusted) , centralized lubrication to moving parts by manual oil pump.

13. Adopting PLC system to achieve the control of each spindle motor and location setting device.

14. Moveable PLC screen , convenient for using.

15. Adopting electric components from international class with steady quality.

16. Sealed safety cover is for the protection against noise and dust, and it is helpful for safe operation.

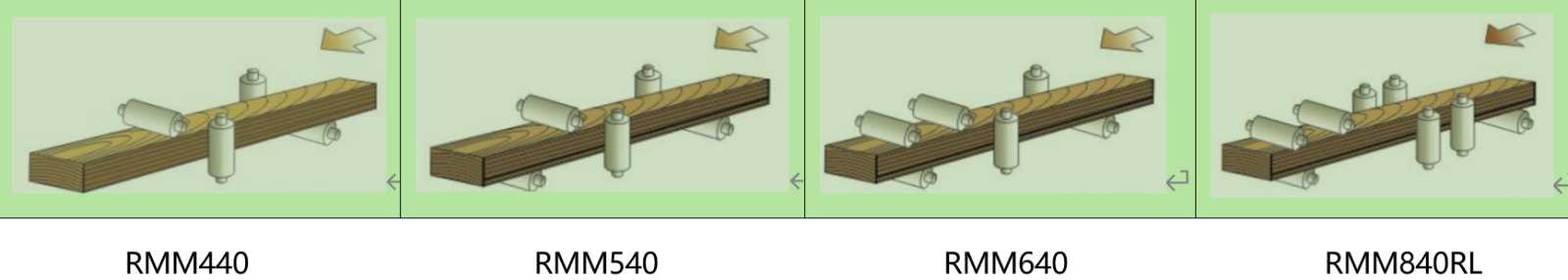

Specification & type |

RMM840RL |

RMM640 |

RMM540 |

RMM440 |

|

|

Working Width (mm) |

Min. |

120 |

120 |

120 |

120 |

|

Max. |

400 |

400 |

400 |

400 | |

|

Working Thickness (mm) |

Min. |

30 |

30 |

30 |

30 |

|

Max. |

300 |

300 |

300 |

300 | |

|

Number of spindles |

8 |

6 |

5 |

4 | |

|

Spindle Speed(r/min) |

6000 |

5000 |

5000 |

5000 | |

|

Cutting circles (max~min)(mm) |

First Bottom Spindle |

Ø160~Ø180 |

Ø160~Ø180 |

Ø160~Ø180 |

Ø160~Ø180 |

|

Right side Spindle |

Ø160~Ø230 |

Ø160~Ø230 |

Ø160~Ø230 |

Ø160~Ø230 | |

|

Left side Spindle |

Ø160~Ø230 |

Ø160~Ø230 |

Ø160~Ø230 |

Ø160~Ø230 | |

| Second Right side Spindle | Ø160~Ø230 | - | - | - | |

| Second Left side Spindle | Ø160~Ø230 | - | - | - | |

|

First Top Spindle |

Ø160~Ø230 |

Ø160~Ø230 |

Ø160~Ø230 |

Ø160~Ø230 | |

|

Second Top Spindle |

Ø160~Ø230 |

Ø160~Ø230 |

- |

- | |

|

Second Bottom Spindle |

Ø160~Ø230 |

Ø160~Ø230 |

Ø160~Ø230 |

- | |

|

Max.OD for installing saw on 2nd bottom spindle |

- |

Ø300 |

Ø300 |

- | |

|

Spindle diameter (mm) |

Ø50 |

Ø50 |

Ø50 |

Ø50 | |

|

Basic motor powers (kW) |

First Bottom Spindle |

15KW/20HP |

15KW/20HP |

15KW/20HP |

15KW/20HP |

|

Right side Spindle |

15KW/20HP | 15KW/20HP | 15KW/20HP | 15KW/20HP | |

|

Left side Spindle |

15KW/20HP | 15KW/20HP | 15KW/20HP | 15KW/20HP | |

| Second Right side Spindle | 15KW/20HP | - | - | - | |

| Second Left side Spindle | 15KW/20HP | - | - | ||

|

First Top Spindle |

15KW/20HP |

15KW/20HP |

15KW/20HP |

15KW/20HP | |

|

Second Top Spindle |

15KW/20HP |

15KW/20HP |

- |

- | |

|

Second Bottom Spindle |

15KW/20HP |

15KW/20HP |

15KW/20HP |

- | |

|

Feed |

11KW/15HP |

11KW/15HP |

11KW/15HP | 7.5KW/10HP | |

|

Feed beam rise & fall |

1.5KW/2HP |

1.5KW/2HP |

1.5KW/2HP |

1.5KW/2HP | |

|

Total motor power(KW) |

132.5KW/177HP |

102.5KW/137HP |

87.5KW/117HP |

69KW/92HP | |

|

Feed speed (m/min) (Inverter for feed ) |

4~20 |

5~25 |

5~25 |

5~25 | |

|

Dust outlet diameter(mm) |

vertical spindles |

Ø150mm |

Ø150mm |

Ø150mm |

Ø150mm |

|

horizontal spindles |

Ø180mm |

Ø180mm |

Ø180mm |

Ø180mm | |

|

Overall machine dimensions (L×W×H) (mm) |

7100×2300×2520 |

5620×2200×1950 |

5000×2200×1950 |

4210×2200×1950 | |

|

Weight(Tons approx) |

19.6 |

12 |

10.5 |

9 | |

Note: Any variation to the specification above mentioned will not be further notified since the product specification and designs keeps on changing.