Professional solution for processing Medium hard wood strip, MDF strip, HDF strip, floor, doors, solid wood furniture and Square boards.

1.Inveter feed speed of 6-30m/min (Optional feed speed 8-40m/min).

2.Individual motor to each spindle to ensure maximum cutting.

3.All spindle adjustment are carried out in front of the machine for convenience.

4.Hard chromed treatment has been adopted for the durability of the work table surface.

5.Chain-wheel box is equipped for advancing the smooth feeding of short piece availably.

6.Bottom driving bed rollers for enhancing feeding performance.

7.Pneumatic pressure loaded to top feed rollers separately adjustable for easy of feeding stock with variation in thickness.

8.Manual lubrication to the work table and carriage , easy to centralized control and shortcut.

9.Adopting electric component from international class with steady quality.

10.Sealed safety enclosure avoid splashing of wood chips and insulate the noises , it is good for the safe protection.

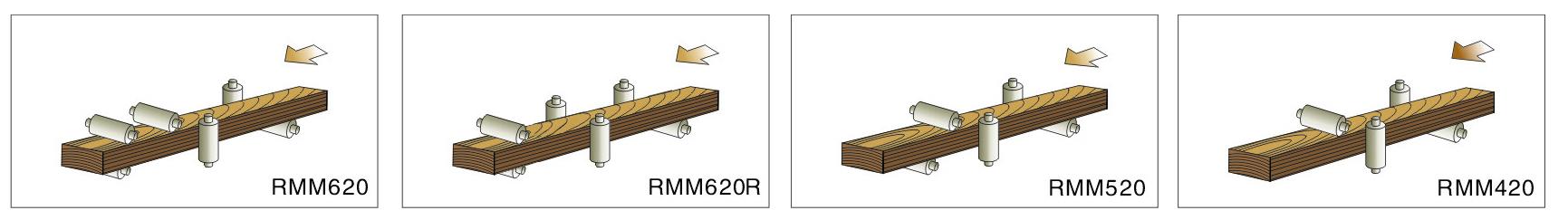

Specification & type |

RMM620 |

RMM620R |

RMM520 |

RMM420 |

|

| Working Width (mm) | Min | 20 | 20 | 20 | 20 |

| Max. | 200 | 200 | 200 | 200 | |

| Working Thickness (mm) | Min | 8 | 8 | 8 | 8 |

| Max. | 120 | 120 | 120 | 120 | |

| Number of spindles | 6 | 6 | 5 | 4 | |

| Speed of spindles(r/min) | 6000 | 6000 | 6000 | 6000 | |

| Cutting circle (min~max) (mm) | First Bottom Spindle | Ø110~Ø145 | Ø110~Ø145 | Ø110~Ø145 | Ø110~Ø145 |

| Right side Spindle | Ø110~Ø180 | Ø110~Ø180 | Ø110~Ø180 | Ø110~Ø180 | |

| Left side Spindle | Ø110~Ø180 | Ø110~Ø180 | Ø110~Ø180 | Ø110~Ø180 | |

| Second right spindle |

~~~~~ |

Φ110~Ø180 |

~~~~~ |

~~~~~ |

|

| First Top Spindle | Ø110~Ø160 | Ø110~Ø180 | Ø110~Ø160 | Ø110~160 | |

| Second Top Spindle | Ø110~Ø160 |

~~~~~ |

~~~~~ |

~~~~~ |

|

| First Bottom Spindle | Ø110~Ø180 | Ø110~Ø180 | Ø110~φ180 |

~~~~~ |

|

| Spindle diameter (mm) | Ø40 | Ø40 | Ø40 | Ø40 | |

| Basic Motor powers (kW) | First Bottom Spindle | 5.5 kW/75HP | 5.5 kW/75HP | 5.5 kW/7.5HP | 5.5 kW/7.5HP |

| Right side Spindle | 4 kW/5.5HP | 4 kW/5.5HP | 4 kW/5.5HP | 4 kW/5.5HP | |

| Left side Spindle | 4 kW/5.5HP | 4 kW/5.5HP | 4 kW/5.5HP | 4 kW/5.5HP | |

| Second right spindle | ~~~~~ | 5.5 kW/75HP | |||

| First Top Spindle | 5.5kW/75HP | 5.5 kW/75HP | 5.5kW75HP | 5.5kW/7.5HP | |

| Second Top Spindle | 5.5 kW/75HP | ~~~~~ | ~~~~~ | ~~~~~ | |

| First Bottom Spindle | 5.5kW/7.5HP | 5.5 kW/7.5HP | 5.5kW/7.5HP | ~~~~~ | |

| Feed | 4kW/5.5HP | 4kW/5.5HP | 3kW/4HP | 3kW/4HP | |

| Feed beam rise &fal | 1.1kW/15HP | 1.1kW/15HP | 1.1kW/15HP | 1.1kW/15HP | |

| Total motor power (kW) | 35.1kW/48HP | 35.1KW/48HP | 28.6kW/39HP | 23.1kW/31.5HP | |

| Feed speed (mm) (Inverter for feed) | 6~30 | 6~30 | 6~30 | 6~30 | |

| Dust outlet diameter (mm) | Ø130 | Ø130 | Ø130 | Ø130 | |

| Overall machine dimensions (LxWxH) (mm) | 4308×1620×1700 | 4245×1620×1700 | 3828x1620×1700 | 2983×1572×1700 | |

| Weight (tons approx) (T) | 4 | 3.8 | 3.5 | 3 | |

Note:Any variation to the specification above mentioned will not be further notified since the product specification and design keeps on changing all the time