Professional solution for processing anti-corrosive wood, wall hanging wooden board, sauna board etc. for high efficient processing of multi-pieces molding.

1. The machine has four side planningr and slice double functions which can save time and enhance capacity effectively

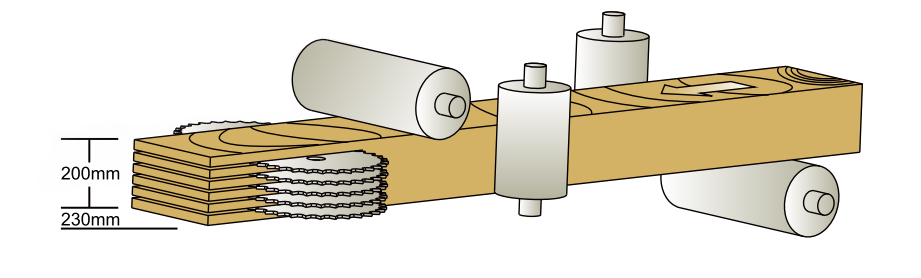

2. Working thickness up to 200mm, to satisfy the great strength of needs for processing range of preservative wood and wooden plywood.

3. Equipped with four groups of driving slave feeding rollers of feeding system out-feed end, which make the workpieces after slicing can out-feed smoothly.

4.Inverter feed speed of 6-30m/min.

5. Individual motor to each spindle to ensure maximm cutting.

6. Two high precision bearings for supporting of the front and backward of the spindle, it is more suitable for heavy cutting.

7.All spindle adjustments are carried out in front of the machine for convenience.

8.Hard chormb treament has been adopted for the durability of work table surface.

9.Equipped with shaft cooling and cleaning function,it can increasing the life of saw blades and ensure the precision of cutting.

10.Chain-wheel box is equipped for advancing feeding performance.

11.A group of side pressure wheels on the right side of the left spindle, adjusted the pressure flexible by pneumatic.

12.As our standard, short pieces device with pneumatic double-direction( press and raise) , you can make the workpieces feeding or back in anytime.

13.Pneumatic pressure loaded to top feed rollers separately adjustable, for easy of feeding stock with variation in thickness.

14.Multiple sets of driving bed rollers for enhancing feeding performance.

15.Adjustable out-feed side pressure board which can more satisfy the smothly output of different thickness of the wood.

16.Manual oil pump lubrication for working table and saddle,it is convenience for control.

17.Configuring dual anti-rebound device in front of the feeding entrance , effectively prevent the rebounding of the wood.

18.Adopting electric component from international class with steady quality.

19.Sealed safety enclose to reduce noise levels, improve extraction and operator safety.

Specification&type |

RMM623SS |

|

| Working width(mm) | Min.For main machine | 20 |

| Max.For main machine | 230 | |

| Min.For saw unit | 60 | |

| Max.For saw unit | 200 | |

| Working thickness(mm) | Min | 20 |

| Max. | 200 | |

| Min.thickness of slice(mm) | 5 | |

| Number of spindles | 6 | |

| Milling cutter shaft speed (r/min)/saw shaft speed (r/min) | 6000/4000 | |

| Cutting circle (min-max)(mm) | First bottom spindle | Ø110-Ø145 |

| Right spindle | Ø110-Ø200 | |

| Left spindle | Ø110-Ø200 | |

| Top spindle | Ø110-Ø200 | |

| Right saw unit | Ø180-Ø300 | |

| Left saw unit | Ø180-Ø300 | |

| Spindle diameter (mm) | Spindle | Ø40 |

| Saw unit | Ø50 | |

| Motor power(kW) | First bottom spindle | 11kW/15HP |

| Right spindle | 11kW/15HP | |

| Left spindle | 11kW/15HP | |

| Top spindle | 11kW/15HP | |

| Right saw unit | 22kW/30HP | |

| Left saw unit | 22kW/30HP | |

| Feed | 7.5kW/10HP | |

| Assist feed | 0.75kW/1HP | |

| Total capacity of installed motor (KW) | 97.75kW/133HP | |

| Speed (m/min) (inverter for feed) | 6-30 | |

| Dust pipe diameter (mm) | Ø150 | |

| Dust pipe diameter (mm) | Ø150 | |

| Overall machine dimensions (LxWxH) (mm) | 4800×1950x196 | |

| Weight (tons approx) (T) | 5.3 | |

Note:Any variation to the specification above mentioned will not be further notified since the product specification and design keeps on changing all the time.