Professional solution: high-speed processing of solid wood floors, wainscoting, four-sided planing of finger-jointed materials, strips, ship boards, etc., with a maximum feeding speed of 50 meters/minute (optional up to 60 meters/minute)

1.Using variable frequency feeding, the feeding speed can reach 10-50 meters/minute, which can quickly increase production capacity. It is a high-efficiency machine (optional up to 60 meters/minute).

2.All spindles diameter are Ø50mm, and two pairs of high-precision bearing support, which are more suitable for heavy-duty cutting.

3.The last spindle reaches 8000r/min and effectively improve the smooth.

4.The last top spindle and the last bottom spindle are equipped with external support bearings, which are more conducive to high-speed cutting.

5.With blade sharpening device at last spindle to reduce workload and raise efficiency.

6.Except for the first spindle operation, the radial adjustment of the rest of the cutter axis is equipped with a digital magnetic scale display, making the tool adjustment faster and more accurate.

7.The heavy-duty machine body structure, through multiple aging treatments, ensures the stability of the high-speed feeding machine.

8.Hard chormb treament has been adopted for the durability of work table surface.

9.Chain-wheel box is equipped for advancing feeding performance.

10.The double-layer plate design of the left and right spindle carriage makes it easier to replace tools with different outer diameters.

11.A group of side pressure wheel on the right side of left spindle, to adjust pressure flexibly.

12.First group of feeding roller and chain-wheel box with pneumatic double-direction adjustment , you can make the workpiece feeding or back-feed.

13.Pneumatic pressure loading to top feed rollers separately adjustable for easy of feeding stock with variation in thickness.

14.Pneumatic pressure loaded to the front and the back shoes of top spindle to adjust flexibly.

15.Multiple sets of driving bed rollers for enhancing feeding performance.

16.The work table surface is lubricated by an electric oil injection pump, and the carriage is lubricated by a manual oil pump. Centralized control makes operation convenient.

17.All spindle adjustments are carried out in front of the machine for convenience.

18.Adopting electric component from international class with steady quality.

19.Sealed safety enclose to reduce noise levels, improve extraction and operator safety.

Specification and model |

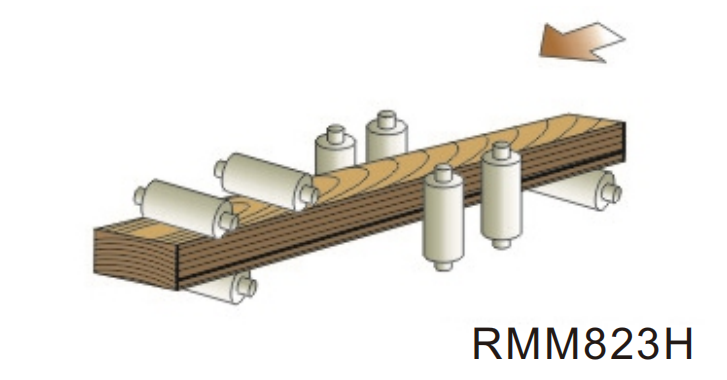

RMM823H |

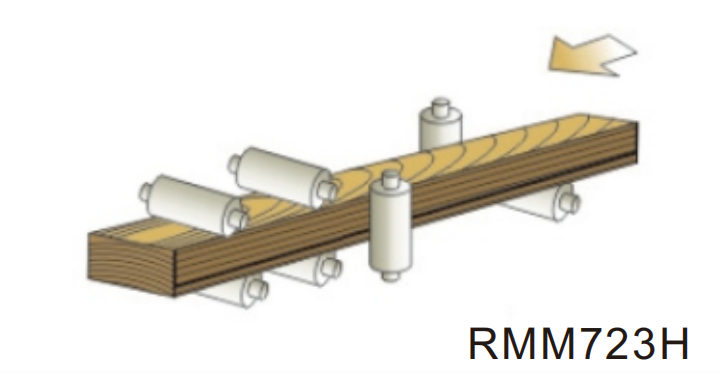

RMM723H |

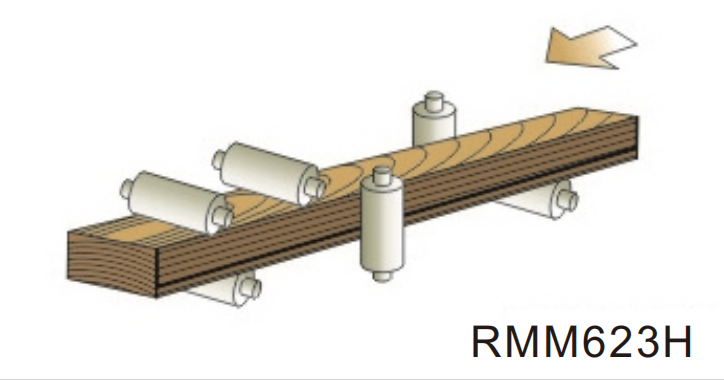

RMM623H |

|

|

Working width(mm)

|

Min. |

20 |

20 |

20 |

|

Max. |

230 |

230 |

230 |

|

|

Working width(mm)

|

Mix. |

8 |

8 |

8 |

|

Max. |

160 |

160 |

160 |

|

|

Number of spindles |

8 |

7 |

6 |

|

|

Number of rotation(r/min)

|

First bottom spindle |

6000 |

6000 |

6000 |

|

First right spindle |

6000 |

8000 |

8000 |

|

|

First left spindle |

6000 |

8000 |

8000 |

|

|

Second right spindle |

8000 |

|

|

|

|

Second left spindle |

8000 |

|

|

|

|

First top spindle |

6000 |

6000 |

6000 |

|

|

Second bottom spindle) |

|

6000 |

|

|

|

Second top spindle |

8000 |

8000 |

8000 |

|

|

Second bottom |

8000 |

|

8000 |

|

|

Third bottom spindle |

|

8000 |

|

|

|

Cutting circle(Min.-Max.)(mm)

|

First bottom spindle |

Ø110 ~ Ø145 |

Ø110 ~ Ø145 |

Ø110 ~ Ø145 |

|

First right spindle |

Ø110 ~ Ø200 |

Ø110 ~ Ø200 |

Ø110 ~ Ø200 |

|

|

First left spindle |

Ø110 ~ Ø200 |

Ø110 ~ Ø200 |

Ø110 ~ Ø200 |

|

|

Second right spindle |

Ø110 ~ Ø200 |

|

|

|

|

Second left spindle |

Ø110 ~ Ø200 |

|

|

|

|

First top spindle |

Ø110 ~ Ø200 |

Ø110 ~ Ø200 |

Ø110 ~ Ø200 |

|

|

Second bottom spindle) |

|

Ø110 ~ Ø200 |

|

|

|

Second top spindle |

Ø110 ~ Ø200 |

Ø110 ~ Ø200 |

Ø110 ~ Ø200 |

|

|

Second bottom |

Ø110 ~ Ø200 |

|

Ø110 ~ Ø200 |

|

|

Third bottom spindle |

|

Ø110 ~ Ø200 |

|

|

|

Spindle diameter (mm) |

Ø50 |

Ø50 |

Ø50 |

|

|

Motor power(kW)

|

First bottom spindle |

7.5kW/10HP |

7.5kW/10HP |

7.5kW/10HP |

|

First right spindle |

7.5kW/10HP |

7.5kW/10HP |

7.5kW/10HP |

|

|

First left spindle |

7.5kW/10HP |

7.5kW/10HP |

7.5kW/10HP |

|

|

Second right spindle |

11kW/15HP |

|

|

|

|

Second left spindle |

11kW/15HP |

|

|

|

|

First top spindle |

11kW/15HP |

11kW/15HP |

11kW/15HP |

|

|

Second bottom spindle) |

|

11kW/15HP |

|

|

|

Second top spindle |

11kW/15HP |

11kW/15HP |

11kW/15HP |

|

|

Second bottom |

11kW/15HP |

|

11kW/15HP |

|

|

Third bottom spindle |

|

11kW/15HP |

|

|

|

Feed |

11kW/15HP |

7.5kW/10HP |

5.5kW/7.5HP |

|

|

Feed beam &fall |

1.1kW/1.5HP |

1.1kW/ 1.5HP |

1.1kW/ 1.5HP |

|

|

Total motor power (kW) |

89.6kW/121.5HP |

75.1kW/101.5HP |

62.1kW/84HP |

|

|

Feed speed(m/min)(Inverter for feed) |

10~50(optional 12~60) |

|||

|

Dust pipe diameter (mm) |

Ø150 |

Ø150 |

Ø150 |

|

|

Overall machine dimensions(LxWxH) (mm) |

6200×1950×1800 |

5580×1950×1800 |

4960×1950×1800 |

|

|

Weight(tons approx (T) |

7.2 |

6.3 |

5.6 |

|

Note: Any variation to the specification above mentioned will not be further notified since the product specification and designs keeps on changing.