Hello! Welcome to the official website of Guangdong Reignmac Machinery Co., Ltd.

Name of Exhibition:Shanghai International Furniture Machinery & Woodworking Machinery Fair

Address:National Exhibition and Convention Center (Shanghai, Hongqiao)

Booth: 8.1D01

Exhibition Time: 2023.09.05-2023.09.08

Shanghai International Furniture Production Equipment and Woodworking Machinery Exhibition (International Woodworking Exhibition) was first established in 1986. After years of development and innovation, it has become one of the largest and most influential exhibitions in Asia. It brings together the entire supply chain resources of the furniture production and woodworking industry, covering a comprehensive and wide range of fields.

REIGNMAC Woodworking Machinery will bring you solutions for reducing labor costs in building structures, glulam, high-speed processing of four-sided planing, as well as edge processing of furniture and cabinets.

Highlights of this exhibition from REIGNMAC woodworking

01

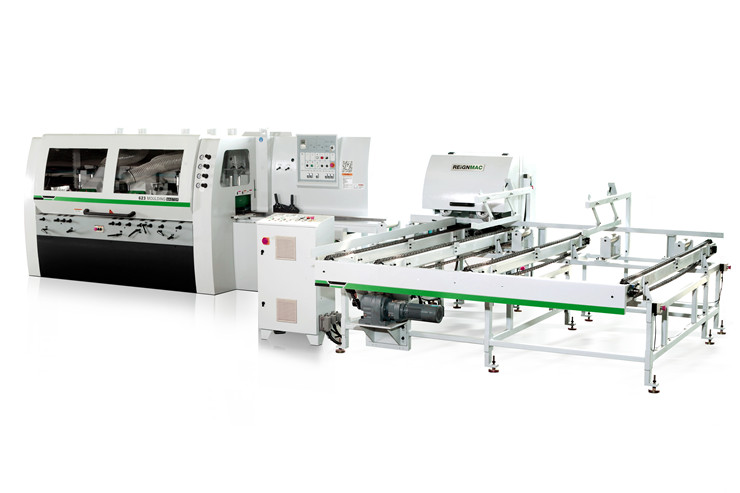

Feeding Speed With 50m/min High-Speed Four Side Moulder

The high-speed 4-sided planer exhibited by REIGNMAC can bring stable and good surface quality in 50-meter high-speed machining. From a single machine to an automated connection, REIGNMAC can provide you with a variety of solutions.

l The three-point support technology of the horizontal spindle makes cutting more powerful

l Online automatic sharpening technology to reduce the frequency of tool replacement

l More accurate tool adjustment display

l Better vacuuming effect experience

02

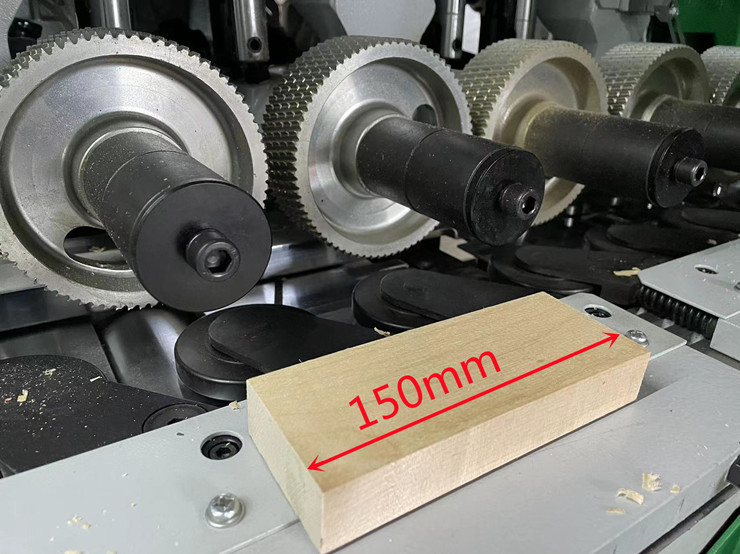

Feeding Speed With 70m/min High-Speed Short Pieces Four Side Moulder

This high-speed four side planer can meet the continuous feeding of materials with the shortest length of 150mm, and the maximum feeding speed can reach 70 m/min.

l The design of the first two sets of lower spindles make the reference surface more flat and the material consumption is less

l Double left and right cutter shafts, reducing material loss and better straightness

l The particularly compact pressing system allows the 150mm length of wood to be fed smoothly

l Auxiliary feeding mechanism equipped with feeding platform

03

Sanding & Milling Compound Double End Tenoner

This is a double-end milling and sanding function combined into one machine, which can solve the edge milling and sanding process of cabinet door panels, bathroom cabinet door panels, and solid wood furniture at one time, saving manpower, space and turnover.

l With jump milling function, it has the effect of preventing edge collapse

l The milling cutter adopts a high-speed variable frequency motor, and the processing finish is better

l The triangular sanding frame has the design of preventing the deviation of the sand belt and preventing the break up for both end of workpieces.

l Multi-purpose sanding head can be used for flat sanding, and can also be used for profile sanding

We sincerely welcomes new and old customers to visit our booth and learn about the new technology of four side moulder and double end tenoner.